The HGG PC 600 is an affordable, sophisticated pipe cutting machine that reduces material handling, increases welder arc on time, and eliminates post-cut welding.

In today’s world, time is everything, which makes a pipe cutting machine a must-have tool in your shop. How long does it take to cut, prep, and weld a pipe joint? How much time does the welder spend welding? If they spend a disproportional amount of time grinding and preparing the weld joint, you will benefit from a CNC steel pipe cutting machine like the HGG PC 600.

What if your company had a pipe-cutting system that eliminated the hours spent grinding? Think about how much more welding could be accomplished in a shift, a week, or a month. Plus, eliminating a large portion of the grinding in your facility will significantly enhance safety. Not to mention, your abrasive spending will drop as well. In this post, we'll show you how efficient a pipe-cutting machine can be and how to operate the tool.

Table of Contents

|

Bonus: Book a personal meeting with a welding engineer to reveal how your shop can make process improvements that save you money and time.

|

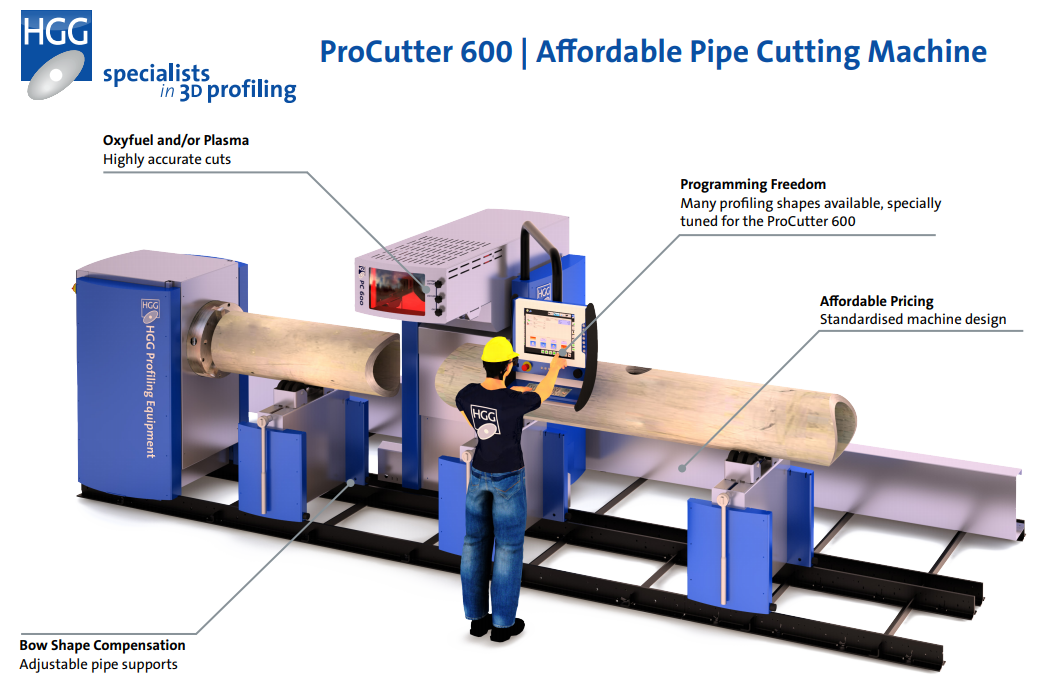

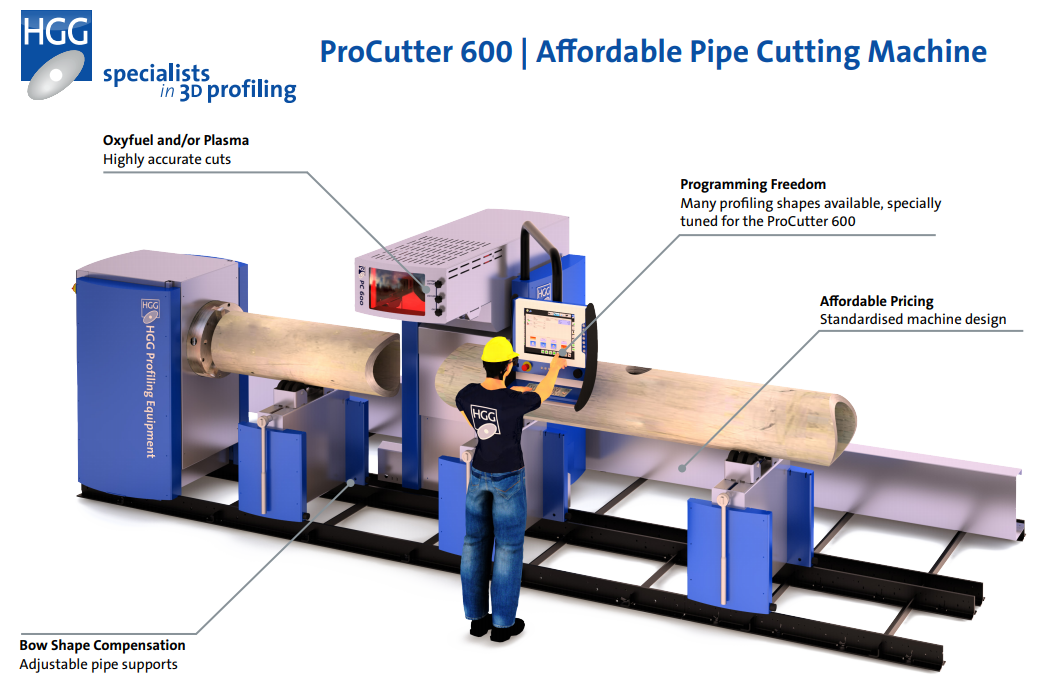

An Overview of the HGG PC 600

The HGG PC 600 is an affordable yet sophisticated pipe cutting and beveling machine that will reduce material handling, increase welder arc on time, and eliminate the need for post-cut welding.

How to use the HGG Pipe Cutting Machine

The PC 600 has the ability to cut 2” – 24” pipe, either carbon or stainless. It can be outfitted with both a plasma and an oxy-fuel cutting system. The pipe is loaded into the chuck, the operator either calls up a part file or programs the cut and then the PC 600 does the rest.

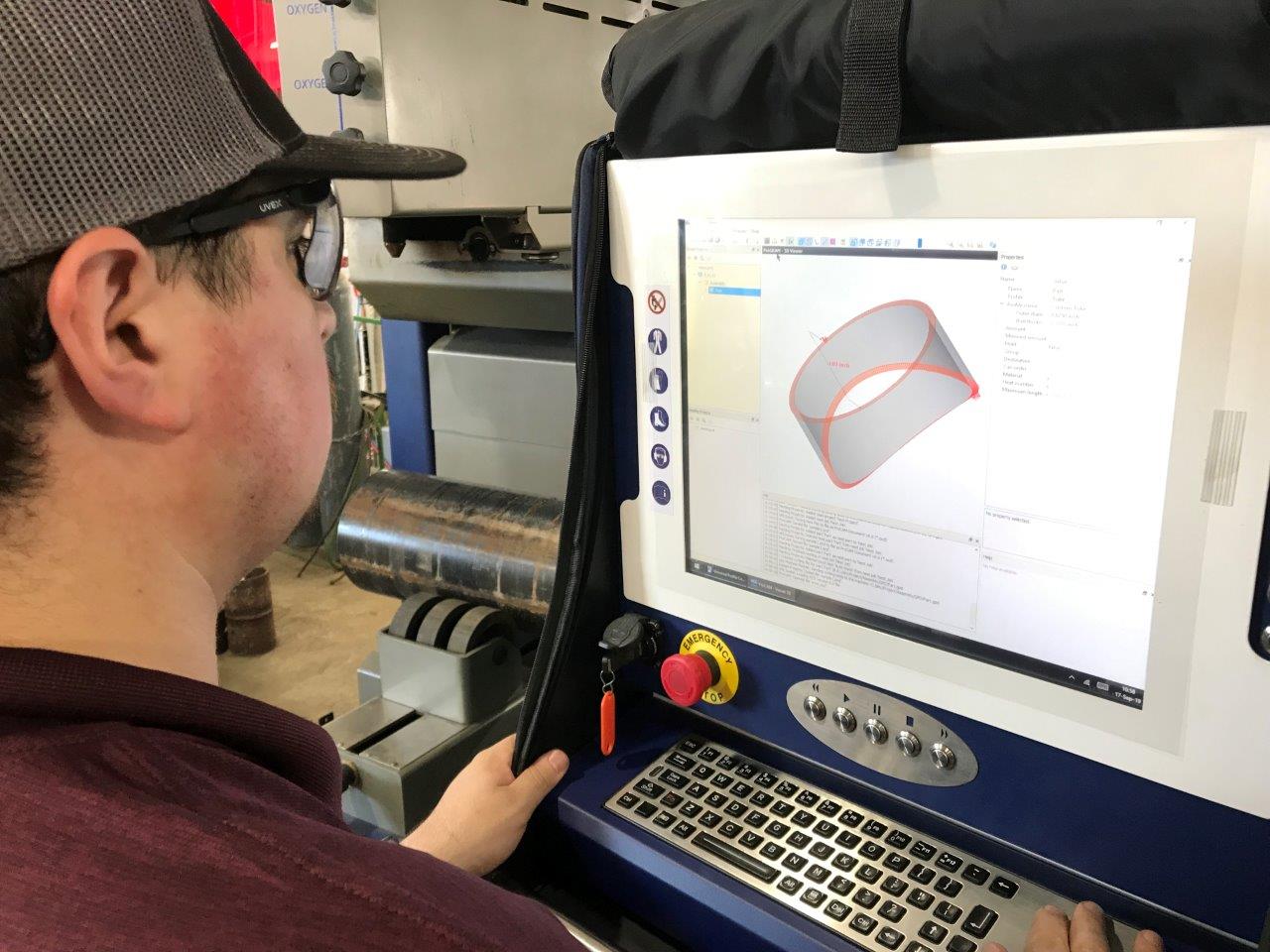

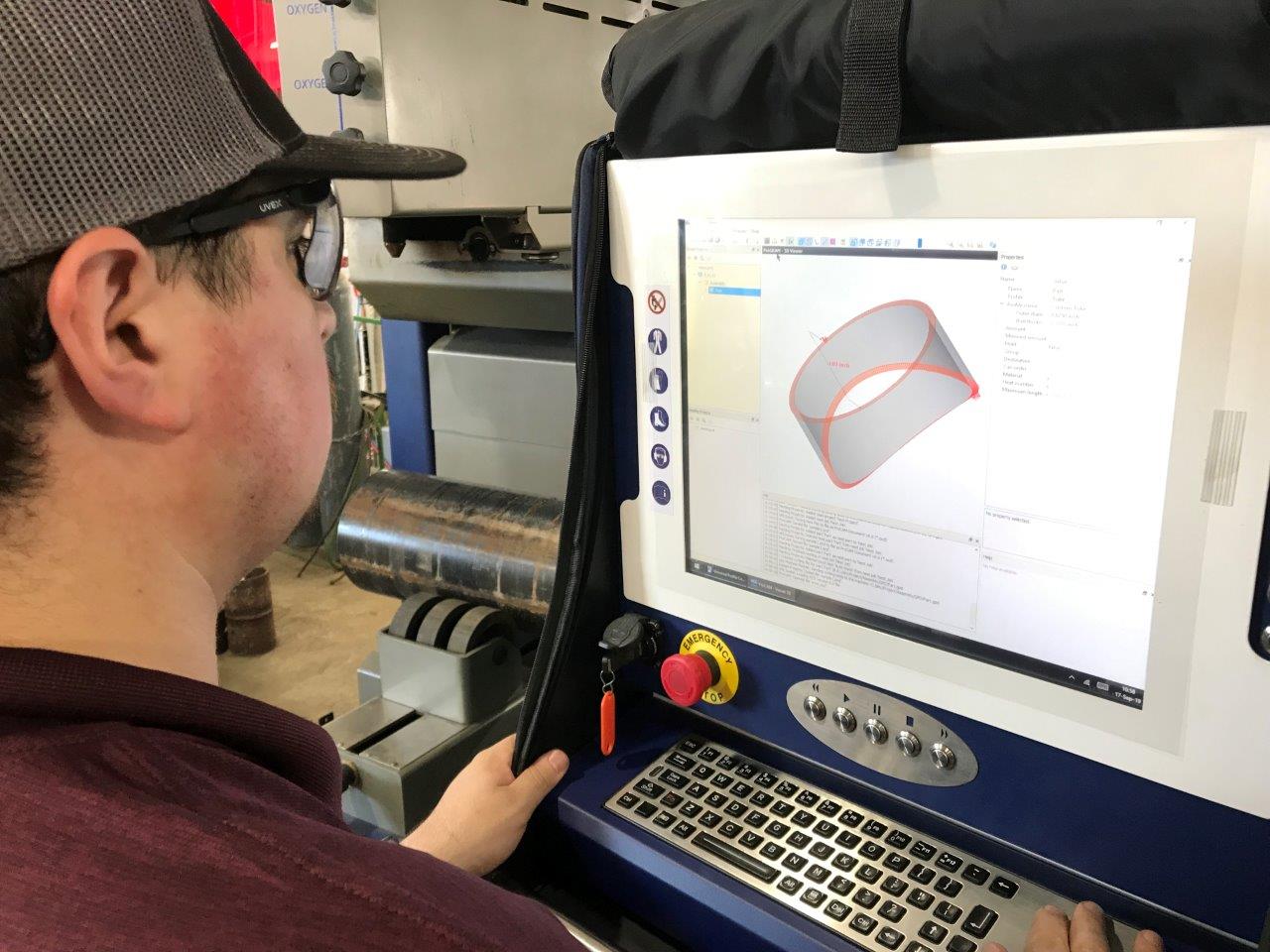

The operator can see the parts in 3D before the cut is made to ensure the shape is correct and the holes are in the correct location. Draftsmen can upload part files to the PC 600 as well to expedite the process.

Cutting can be done by plasma or oxy-fuel for the thicker members. We’ve gotten great results utilizing the Hypertherm Powermax 125 system. These pictures demonstrate the cut quality directly after pipe cutting.

Where to Buy a Pipe Cutting Machine

If you are interested in seeing how the HGG PC 600 can revolutionize your cutting process, contact our Technical Team or schedule a visit to the Red Ball Oxygen Welding Lab. We have this pipe cutting machine for sale and various automation tools available to demo.

Learn how to beat inefficiencies, save time and money, and demo equipment for your fabrication shop. With a personalized assessment, you can get actionable insights on how to improve your process and operation with little downtime.

Disclaimer: This post is in partnership with HGG. All equipment mentioned is listed for sale with Red Ball Oxygen. All opinions and reviews are our own.