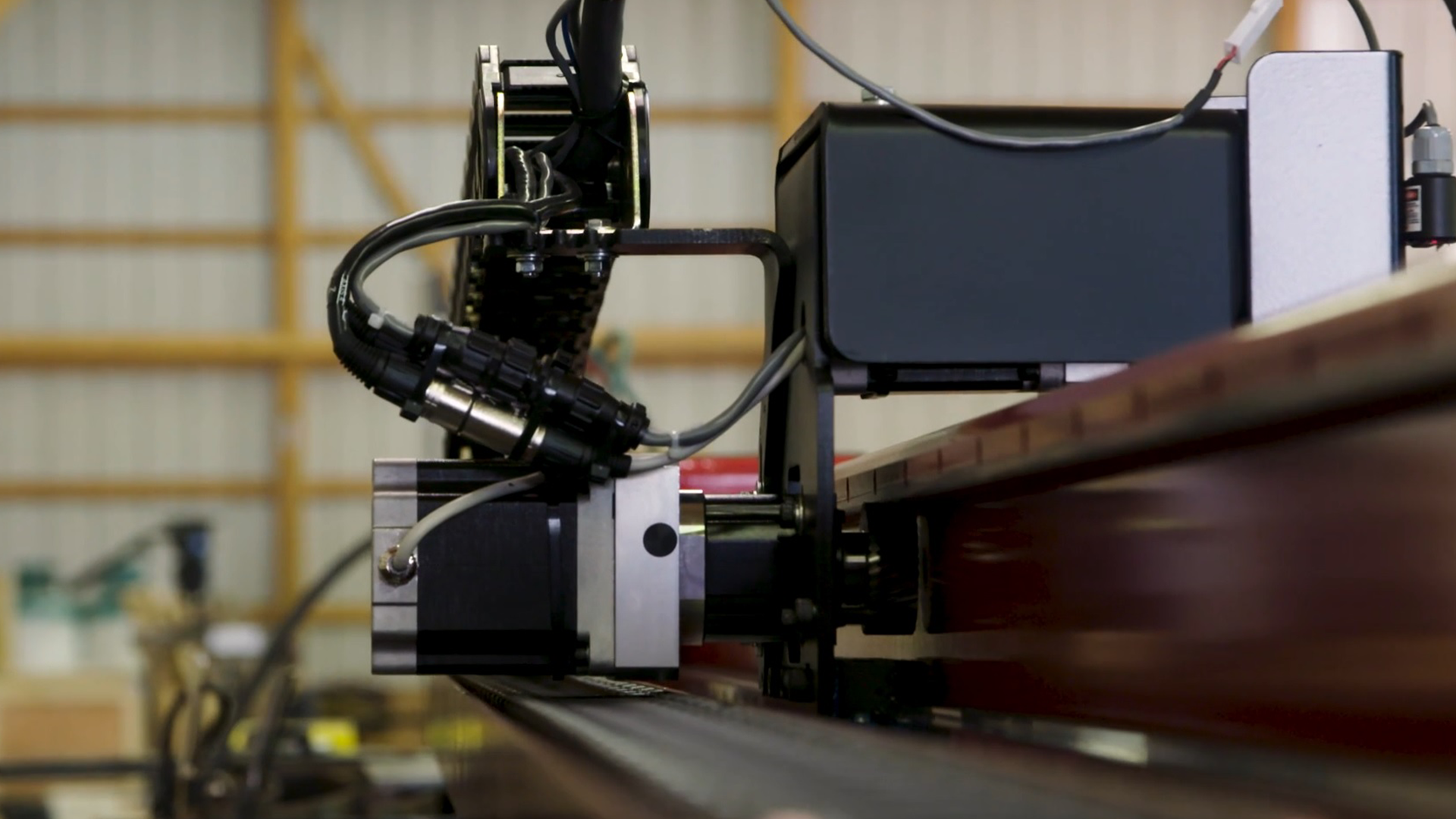

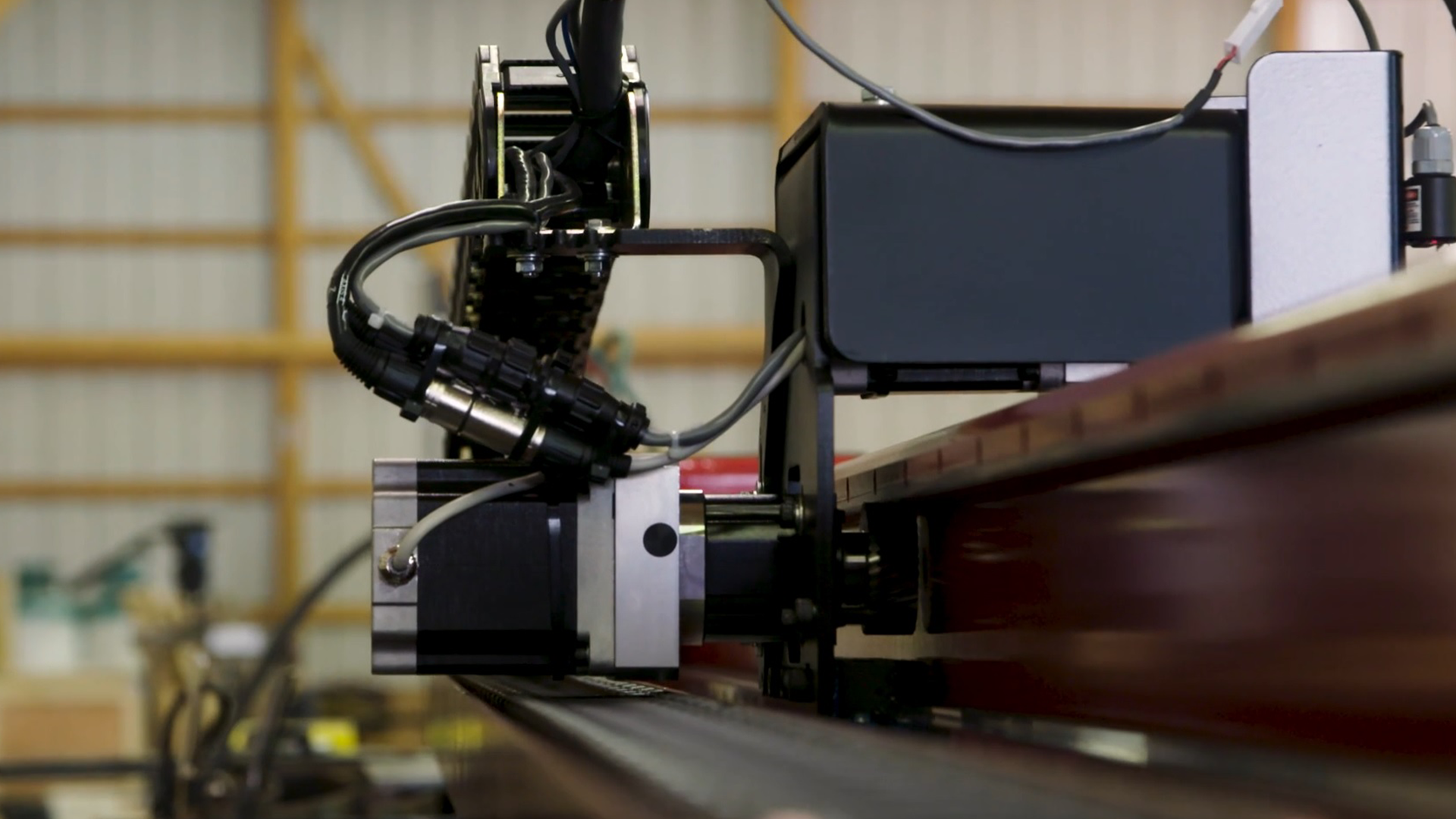

We spotlight the Koike 5X10 Shop Pro Plasma Table, one of the many industrial welding machines housed in our Welding Lab for demos.

Among the many valuable pieces of equipment in our state-of-the-art welding lab, one of my favorites is the Koike Shop Pro Plasma table. Our table is paired with a Hypertherm 125, which has the piercing capability of 1.25”. The Pro Plasma Table can be used for many applications, from cutting out parts in a production shop to cutting ornamental pieces.

A fun feature about the table and software is the ability to pull images offline to edit and cut them right out. This feature gives you the ability to cut custom parts for customers with great precision and low design time.

A couple of things we have built have been a custom fire pit and a sign for our welding lab. We pulled these images from the internet and “cleaned up” the lines for our cutting capabilities. The table is easy to work, and the solid clean edge design makes it fit in any shop, even against a wall.

The software is simple to navigate, and the line feature can be used to draw parts to their size. Once you have all your parts drawn and your image “cleaned” up, import your image, and then place it on the panels. After you place your image(s), you can easily resize each image to fit accordingly. Once you have your drawing complete, you can move to the next step. On this step of the program, you set your material and plasma settings, which will automatically set to your travel speed for cutting, this software makes this so simple. At this point, you have the option to nest your designs. Nesting allows you to minimize the raw material loss in your project. In some cases, you could cut two complete fire pits or 5-6 of the signs out of one 4x8 sheet then proceed to the next step.

Finally, we line up the laser on the corner of the plate to calibrate it and hit the go button. It is a true joy to watch your creation come to life.

The Koike Aronson ShopPro is just one of the several equipments at Red Ball Oxygen Technology Center. The technology center provides our customers with an option to try out these equipment and learn best practices from our in-house welding engineers. Contact us if you would like to see the Koike Aronson ShopPro in action.